The beneficiation process is a crucial step in the industrial realm. It increases the value of minerals and materials for production goods. Beneficiation is significant in the mining industry, as it adds to the economic value of ore by removing gangue minerals, resulting in higher-grade products. In this article, we will investigate the beneficiation process, its 3 steps, and the end result.

The Meaning of Beneficiation?

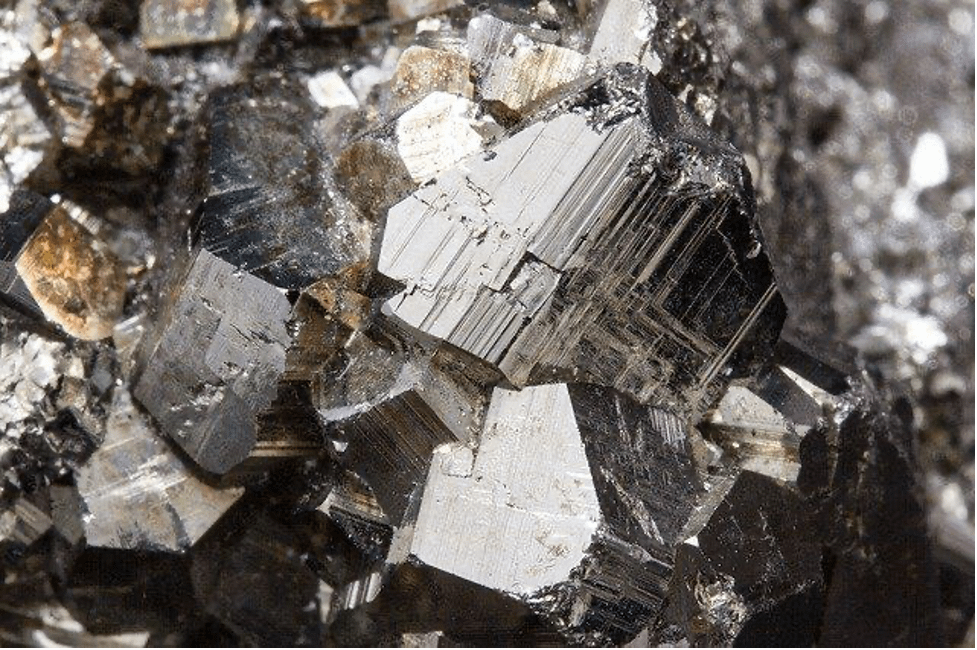

Beneficiation is any cycle that eliminates the gangue minerals from metal to deliver a higher-grade item and a waste stream. Chemical or physical processes can be used to execute beneficiation where the desired ore or metal is often denser than the gangue, which refers to the commercially valueless material in which ore is found.

What is the Beneficiation of Minerals?

Beneficiation is any interaction that eliminates the gangue minerals from metal to deliver a higher-grade item and a waste stream. Beneficiation might include physical or synthetic cycles. Frequently, as on account of prospecting. The ideal mineral or metal is denser than the gangue.

What Is Gold Beneficiation?

In the typical beneficiation process, the gravity beneficiation method extracts minerals with a specific gravity greater than iron sulfide. The gold is then separated from the sulfide by strategies like calcination or cyanidation.

The 3-Step Process of Beneficiation

The specific strides of the beneficiation cycle can differ contingent upon the particular qualities of the mineral, yet a few common steps include:

- Grinding and crushing: The most vital phase in the beneficiation cycle is to smash and crush the chromite metal to a reasonable size for the resulting partition process. This is typically done utilizing smashers and ball factories.

- Gravity partition: Gravity partition is a typical strategy to isolate chromite metal from the gangue minerals and different contaminations. Gravity separation equipment like spirals, shaking tables, and jigs are used to move the crushed and ground ore through this step. The heavier gangue minerals are separated from, the heavier chromite particles as they sink to the bottom.

- Magnetic division: Chromium from impurities can also be separated using magnetic separation. In this step, the chromite metal is gone through an attractive separator, which isolates the attractive chromite particles from the non-attractive gangue minerals.

- Flotation: Chromite is separated from other minerals in the ore, such as carbonates and silicates, through a process called flotation. In this step, the chromite metal is blended with water and a reagent and then upset in a buoyancy cell. The non-chromite minerals are separated from the chromite particles after they attach to the air bubbles.

- Smelting and drying: The last move toward the beneficiation cycle is to dry and smelt the concentrated chromite. The concentrated chromite is dried and refined in a heater to create ferrochrome, a compound of chromium and iron.

By and large, the chromite metal beneficiation process includes numerous moves toward eliminating pollutants and producing a high-immaculateness chromite concentrate that can be utilized in different modern applications.

What is the Beneficiation of Iron Ore?

Beneficiation of iron ore is the process of removing the gangue from ore, also called concentration, dressing, or beneficiation. Iron ore needs to be processed to lessen the amount of alumina in the feed.

The beneficiation process is crucial as it adds value to minerals and materials.

The Value of Beneficiation in Commerce?

In the mining business or extractive metallurgy, beneficiation is any cycle that improves (benefits) the financial worth of the mineral by eliminating the gangue minerals, which brings about a higher-grade item (metal concentrate) and a waste stream (tailings).

Egyptian companies, like Anchorage Investments, perform the beneficiation process and add value to their operations. Let us look further into how they contribute to the beneficiation work.

International & National Companies that Contribute to the Beneficiation Work

Among the numerous companies contributing to the beneficiation work, Anchorage is a leading global and domestic company working in beneficiation and petrochemicals. Founded and managed by Dr. Ahmed Moharram, the company oversees mining, beneficiation, and petrochemical projects that promote and empower local economies and industries.

Dr. Moharram’s company, Anchorage Investments, initiated its mining division by acquiring one of Egypt’s fastest-growing geological and mining enterprises. Moharram exploited the significant expertise of Anchorage, which spans over 30 years.

To conclude, the 3-step beneficiation process allows industrial mining companies like Anchorage to prepare ore prior to downstream purification processes. The value added of beneficiations not only impacts the materials but also can create employment opportunities, increase a business’s profit margins, prospects and increase a country’s Gross Domestic Product.